Contact us

Your Cart

0 Product Products

0 Product Products

No products

TBD

Shipping

$0.00

Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart.

There is 1 item in your cart.

Total products

Total shipping

TBD

Total

DEPTH OF CURE COMPARATOR

View larger

View larger

New product

A problem which exists for the user of UV curable materials is the degree of cure to which a coating formulation has achieved. The CON-TROL-CURE® DEPTH OF CURE COMPARATOR™ provides an easy method to identify the latitude of curability or curing range of the coating. The simplicity and the low cost of this item will allow for a fast evaluation of the coating or ink as frequently as necessary.

The DEPTH OF CURE COMPARATOR™ is designed to evaluate the parameters of a coating in the actual manufacturing environment. As a production tool, it can help identify what is causing a curing problem, as well as establish the specific curing variables (i.e. process speed, UV light intensity, applied coating thickness). With these process variables identified on the comparator, the ability to establish repeatable manufacturing methods is then easy.

The DEPTH OF CURE COMPARATOR™ can be used as a tool for the quality control and evaluation of inks whose cure range has been established. Inks from different lot numbers or age can be evaluated and the exact cure parameters adjusted accordingly.

With a coating of known cure values, the DEPTH OF CURE COMPARATOR™ can the compare the efficiency of UV cure reactors or even indicate when to change a lamp. The results of the Depth of Cure Comparator tests provide a quick and simple method of monitoring the curing process. No longer do plant personnel need to assume the quality of the product.

TESTING METHOD:

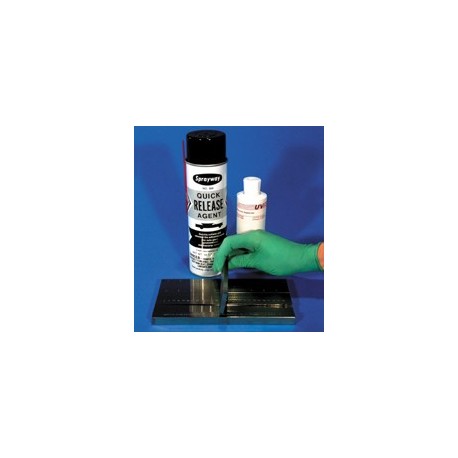

The paths are filled with the ink or coating to be tested and leveled with the accompanying precision milled steel scraper. The DEPTH OF CURE COMPARATOR™ is then placed through the UV curing reactor, exposing the coating to the same conditions used in production. The cured film can then be peeled from the paths for a close and thorough physical examination.

FEATURES:

Compares the coatings performance on the actual curing system

Enables the removal of cured films for additional testing and record keeping

Can be used as a quality control tool for checking incoming curable material

Effectively determines the color opacity level

Effectively determines optimum conveyor speeds

Registers performance differences from batch to batch

Can give additional information related to the effectiveness of lamp intensities

ACCESSORIES SUPPLIED WITH DEPTH OF CURE COMPARATOR™:

Release Agent: Quick Release N008-018 (prevents adhesion to the Comparator)

Magnetic End Tap (prevents coating run-off)

Precision Scraper (levels coating)

Coating Stripper: Bond Breaker N008-017 (removes cured ink or coatings)

SPECIFICATIONS:

Nickel plated

Heat treated hardened steel.

Precision grounded graduated paths.

Ground tool steel to precise flatness which will insure absolute readings.

Channel #1 - 0 to 1/mil.

Channel #2 - 0 to 10/mil.

Channel #3 - 0 to 125/mil.

Device is clearly marked for easy reference.

4"/wide

1/2"/thick

4 1/2-lbs.

3/4"/channels.

The DEPTH OF CURE COMPARATOR™ is designed to evaluate the parameters of a coating in the actual manufacturing environment. As a production tool, it can help identify what is causing a curing problem, as well as establish the specific curing variables (i.e. process speed, UV light intensity, applied coating thickness). With these process variables identified on the comparator, the ability to establish repeatable manufacturing methods is then easy.

The DEPTH OF CURE COMPARATOR™ can be used as a tool for the quality control and evaluation of inks whose cure range has been established. Inks from different lot numbers or age can be evaluated and the exact cure parameters adjusted accordingly.

With a coating of known cure values, the DEPTH OF CURE COMPARATOR™ can the compare the efficiency of UV cure reactors or even indicate when to change a lamp. The results of the Depth of Cure Comparator tests provide a quick and simple method of monitoring the curing process. No longer do plant personnel need to assume the quality of the product.

TESTING METHOD:

The paths are filled with the ink or coating to be tested and leveled with the accompanying precision milled steel scraper. The DEPTH OF CURE COMPARATOR™ is then placed through the UV curing reactor, exposing the coating to the same conditions used in production. The cured film can then be peeled from the paths for a close and thorough physical examination.

FEATURES:

Compares the coatings performance on the actual curing system

Enables the removal of cured films for additional testing and record keeping

Can be used as a quality control tool for checking incoming curable material

Effectively determines the color opacity level

Effectively determines optimum conveyor speeds

Registers performance differences from batch to batch

Can give additional information related to the effectiveness of lamp intensities

ACCESSORIES SUPPLIED WITH DEPTH OF CURE COMPARATOR™:

Release Agent: Quick Release N008-018 (prevents adhesion to the Comparator)

Magnetic End Tap (prevents coating run-off)

Precision Scraper (levels coating)

Coating Stripper: Bond Breaker N008-017 (removes cured ink or coatings)

SPECIFICATIONS:

Nickel plated

Heat treated hardened steel.

Precision grounded graduated paths.

Ground tool steel to precise flatness which will insure absolute readings.

Channel #1 - 0 to 1/mil.

Channel #2 - 0 to 10/mil.

Channel #3 - 0 to 125/mil.

Device is clearly marked for easy reference.

4"/wide

1/2"/thick

4 1/2-lbs.

3/4"/channels.

1229 W. Cortland St. · Chicago, IL 60614-4805 · Phone: 1-800-621-1296 OR 773-248-0099 · Fax: 1-800-99FAXUV OR +1-773-880-6647· Email: info@uvps.com

© COPYRIGHT 2019 U V Process Supply, Inc.